기본정보

| 모델 번호. | MH-HP |

| 구조 | 프레임 유형 |

| 누르는 모양 | 플랫프레스 |

| 플래튼 표면 압력 | 고압 |

| 프레싱 레이어 | 멀티 레이어 |

| 작업 모드 | 마디 없는 |

| 제어 모드 | CNC |

| 자동 등급 | 자동적 인 |

| 인증 | CE, ISO |

| 판매 후 서비스 | 일년 |

| 일하는 방법 | 자동 로딩 및 언로딩 |

| 적합한 합판 크기 | 1250*2500mm |

| 무게 | 65톤 |

| 핫 플레이트 크기 | 2700*!370*52mm |

| 의식 | 30 또는 사용자 정의 |

| 압력 | 800톤 |

| 애플리케이션 | 합판 생산 |

| 이름 | 30 일광 핫 프레스 기계 |

| 운송 패키지 | 플라스틱 필름 |

| 사양 | 3600*1370*7000mm |

| 등록 상표 | 민흥 |

| 기원 | 중국 |

|

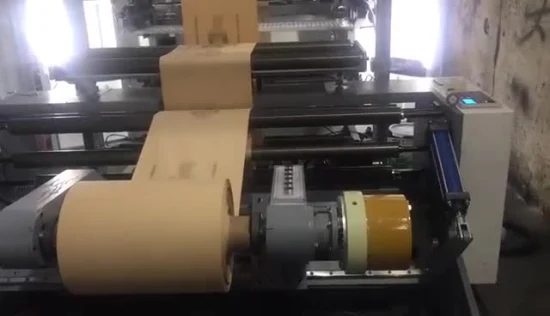

>> The Introduction of Automatic Hot pressing line:30 daylights hot press machine with automatic loading and unloading, the whole pressing line, no need any worker, the working way are totally automatic, Automatic loading plywood into auto infeeder, and auto infeeder automatically convey plywood into hot press machine, after hot press pressed plywood, the plywood will automatically come out and automatic stacking. So the whole hot pressing line are high efficiency and save labor cost. For the 30 daylights hot press machine, you can press 30pcs plywood at the same time. Also we can customize its daylights according to your needs, for example, 25 daylights, 20 daylights, 15daylights, or others. And for the plywood hot press machine pressure, it can be different according to your plywood thickness and other conditions, for example, it can be 800ton, 100ton, for less layers, also can be 600ton and 500ton.For the whole plywood hot pressing line, we use very good materials and spare parts and components. to make sure the hot press machine will works very well, make sure the pressed plywood good quality, and at the same time, you no need spend time to maintain it, our hot press machine long life span. >>> The details of Plywood Hot pressing line:brWhen the hot press machine layers become more, it is not just simple to increase its layers, When hot press layers become more like 30layers, 40layers, During production, many steps will become more complex and strictly to make sure the whole hot press machine working conditions. >>> The Introduction of Our factory-China Plywood Machine Factory:brWe as China big and professional factory who manufacture and offer the complete line of plywood machinery and veneer machine, has been in this industry more than 20 years. We can offer all necessary machines for making veneer and plywood for you. Machines include: Veneer peeling line(Debarking machine, Rotary peeling machine, Log conveyor, Automatic stacker); Magnetic blade sharpener; Veneer drying line (Roller dryer, Mesh wire dryer, Press dryer); Core veneer composer; Veneer patching machine; Plywood pre-press machine; Hot press machine; Film faced hot press machine; Melamine faced hot press machine; Plywood edge sizing trimming machine; Sanding and calibrating and polishing machine; Plywood panel turnover machine; Lift table; Steam boiler and oil boiler.With many years production experience, advanced equipment, experienced workers, professional technicians and engineers, make sure that our machine will be very good. And professional sales team and after sales team, to offer you quick service. So if you choose us, the whole process from order machine, production, loading, machine installation, after sales service, you no need worry anything, we will always be there to stare at it. >>> Our plywood machine loading pictures:brUntil now, our plywood machine and veneer machine has been delivered to many countries, and got good feedback, many clients has bought our machine four or five times, and they are glad to introduce their friends to us. Thats because we are insist to offer suitable, good, and strong machines for them. >>> Other plywood machine you may interested:brThese two machines are Plywood cold press machine, and glue spreader. They are also necessary machine for making plywood. Welcome contact us for more information about hot press machine and other plywood machine and peeling machine, we will reply you quickly.br>